How can a material repair itself?

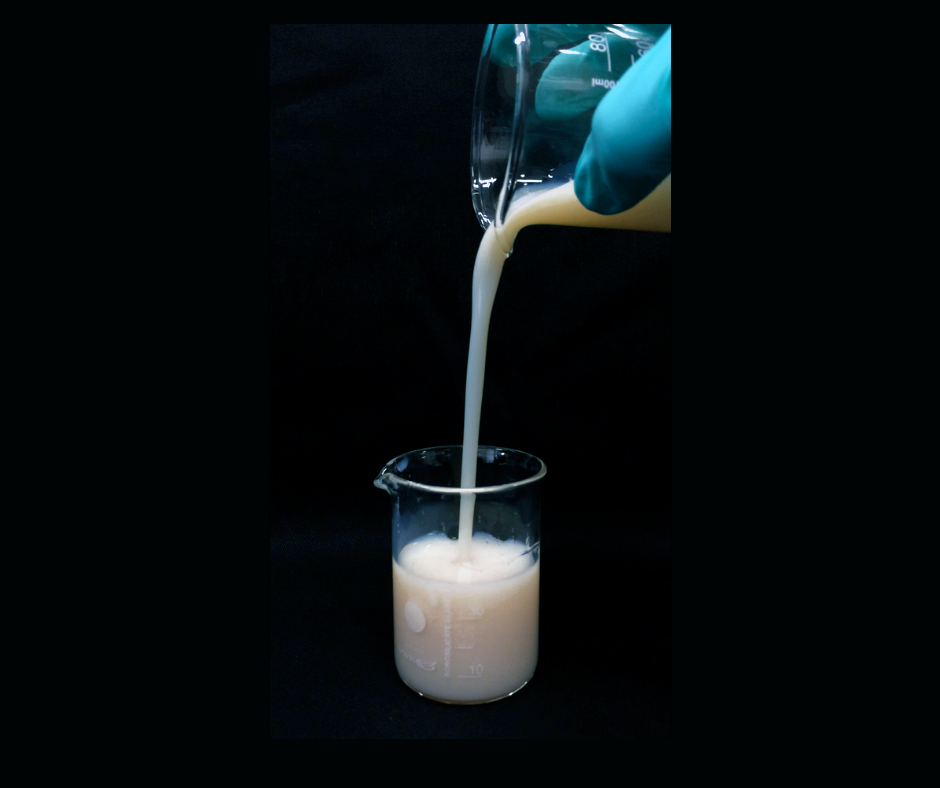

The design of materials capable of repairing themselves, either spontaneously or under the effect of a stimulus, makes it possible to improve their lifespan and their reliability while reducing maintenance costs. This approach, which is eco-responsible, reduces the consumption of polymer materials and the production of waste. This technology can be applied in many fields to restore the original appearance and properties of materials. PolymerExpert designs custom-made healing materials to best suit your needs.