Scaling up: first step before production

To meet your needs, we evaluate the protocol provided and study its feasibility. An optimization of the protocol that can go from a few adjustments to the total redesign of the manufacturing process is then suggested. Recommendations on the analytical plan (ICC: In-coming control and IPC: In process control) to ensure the smooth running of the synthesis and its reproducibility are also communicated to you.

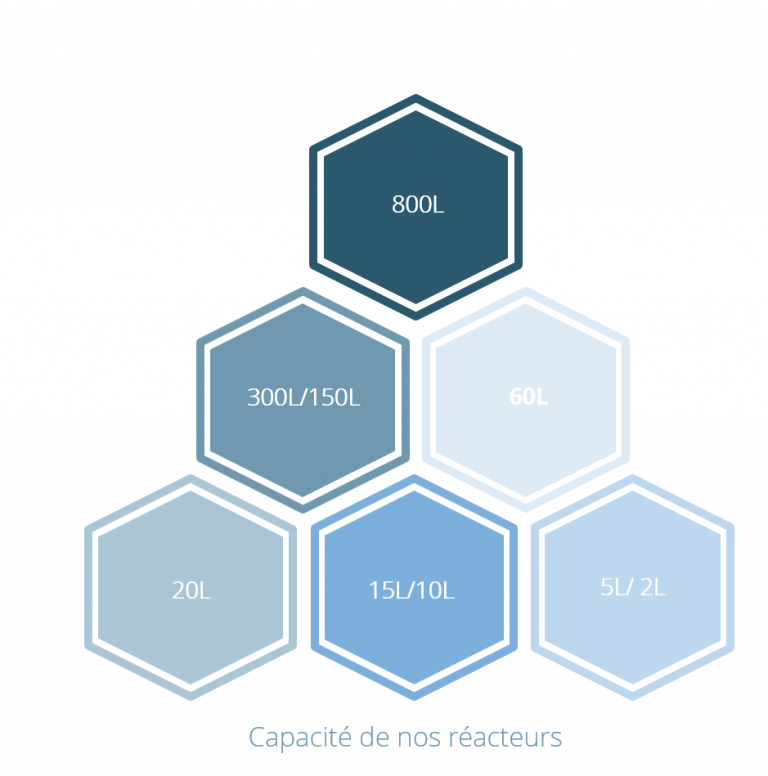

The scale-up is done progressively thanks to the availability of reactors of different capacities. It allows our partners to manufacture clinical batches or to carry out pre-series to validate the industrial feasibility of their innovations.

Implementation of quality monitoring

The production and quality departments work closely together to guarantee compliance with ISO 9001 and ISO 13485 standards from the scaling-up stage. For each production, a manufacturing file is drawn up. This document lists all the synthesis stages and crucial information for the operator. In addition, a risk analysis can be carried out to anticipate possible failures and implement preventive measures. The quality department is in charge of the release of the raw materials and the finished product.

Routine polymer production

PolymerExpert has numerous reactors ranging from 1L to 800L with intermediate sizes. This equipment allows us to adapt production volumes to the different markets. Thus, PolymerExpert provides its customers with the exact quantities they need for their applications. In addition, our activity in the medical sector has led us to dedicate specific environments (ISO 5, 7 and 8 clean rooms). To avoid cross-pollution, we are able to dedicate reactors to certain customers or certain chemistries. These precautions guarantee the conformity of the products and the absence of impurities. The flexibility of our organization allows us to respond to the demands of our customers, from one kilolab to several tons per year.

As PolymerExpert’s production capacity is limited to a few dozen tons per year, PolymerExpert can transfer the production to a manufacturer with a larger capacity. We mainly work with French manufacturers whose production capacity is around 10 tons per batch. Thus, we bring solutions to customers who have needs of several hundred tons per year. Our specialist engineers go directly to the service provider to follow the manufacturing of your products in compliance with the pre-established specifications.

Examples of productions realized

Raw materials in the fields of ophthalmology, electronics, dental and cosmetics

Polymer used for blood filtration

Slip coating

Hydrophobic coating

Polymer used for surgical adhesives

Rheology modifiers