PolymerExpert has been recognized as the “Most Innovative Polymer Manufacturer 2024” by Global Health & Pharma Magazine.

This prestigious award celebrates PolymerExpert’s pioneering work in the field of polymer innovation and highlights its ongoing commitment to advancing material science.

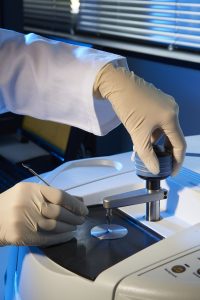

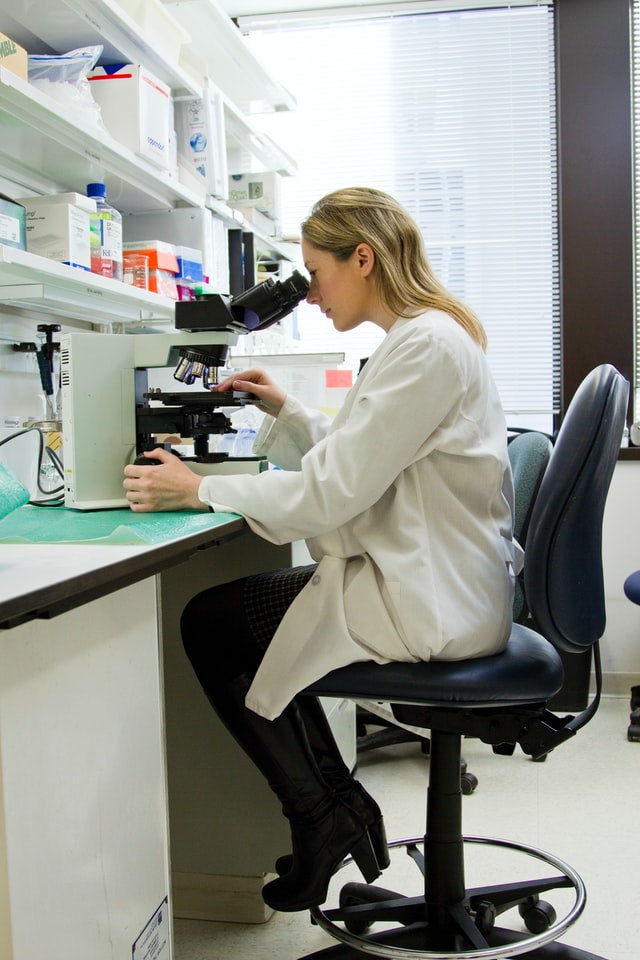

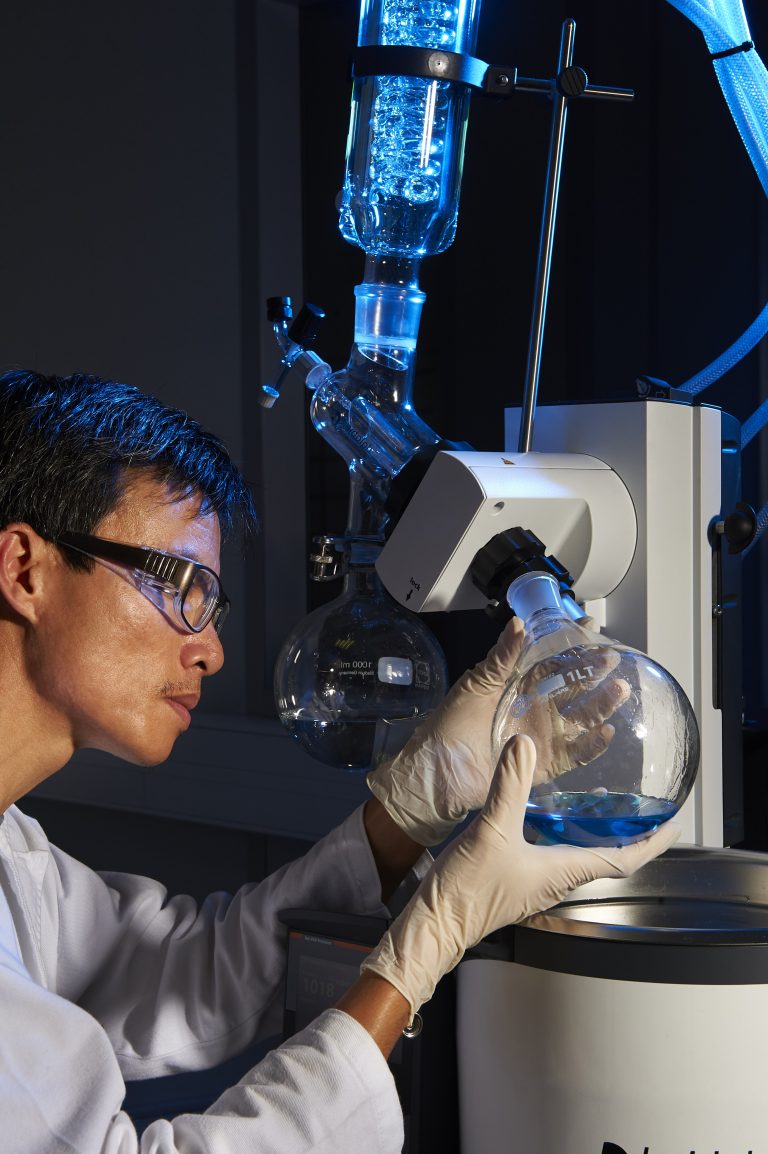

Over the last decade, PolymerExpert has invested heavily in research and development, resulting in breakthroughs that address some of the most complex challenges in polymer science. The company’s state-of-the-art R&D facilities and expert teams have helped position PolymerExpert as a global leader in the polymer manufacturing sector.