The automotive, aeronautics and space sectors are not subject to the same constraints in terms of economics, mechanics or part sizes. However, they are all concerned by the issue of weight reduction, which mechanically generates a reduction in fuel costs but also a considerable environmental impact.

Based on this approach, composite materials appeared in the 1950s. Resulting from an assembly of at least two immiscible materials (with a strong adhesion capacity), they deploy new properties that their constituent elements do not possess alone. Made of an organic matrix (thermoplastic or thermosetting resin) and reinforcements (fibers or fillers), these composites offer many advantages:

- Mass gain: Compared to metals, composites have a low density. The quantity of atoms per unit volume is less important, thus conferring a less important weight;

- Increased safety: the fibrous nature of the material prevents sudden breakage or crack propagation;

- No corrosion;

- Simplified manufacturing: thanks to 3D modeling and additive manufacturing;

- Comfortable margins of safety but minimal enough to remain competitive;

- Soundproofing: it reduces engine noise;

- Possibility of recycling certain materials.

Cost reductions induced by the use of composite parts

In the aeronautical sector, the use of composite parts, instead of metallic alloys, allows a 20% reduction in the weight of an aircraft. In addition to the weight savings, the operating cost becomes more profitable thanks to the use of parts that are more resistant to fatigue and damage and can be repaired.

Simplification of parts by integrating functionalities also allows to reduce the overall cost. Indeed, today there are intelligent composites, combining all the above-mentioned advantages with one or more specific properties. Overall, the use of these composites offers further advantages in terms of cost reduction, even if the cost price of the basic components remains high.

Other characteristics of composites in the aeronautics and space sector

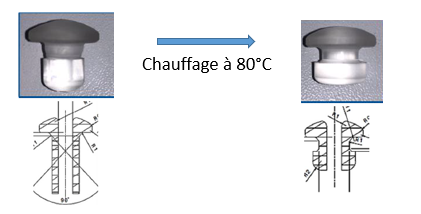

PolymerExpert is currently developing prototypes of shape memory polymer rivets, which are lighter and faster to assemble than steel rivets. The use of these innovative rivets is particularly interesting in the aerospace industry. Replacing the 1.6 million steel rivets on an Airbus 340 with shape memory polymer rivets would reduce the aircraft’s weight by more than one ton.

These shape memory polymer rivets are very easy to assemble. They change shape irreversibly in a few seconds at a temperature of about 80°C.